A TRICKY JOB: KNOW THE SITE CONSTRAINTS (PART 2)

Last week we discussed the design implications behind a tricky site with 120 piles @ 25m long taking loads between 200kN and 700kN… all spread out within a large existing structure. This week we’ll review the importance of site restrictions and how it can significantly influence the price and program of a screw piling project.

DEFINING THE HEADHEIGHT RESTRICTIONS

Our first task on jobs like this is to get accurate measurements on the distance between the floor and the ceiling at EVERY pile position. We do this so that we can calculate the number of sections.

WHAT’S A SECTION?

We define a pile section as the number and length of pipe/s that are required to install a pile.

For example, a 24m long pile in a green fields site might be installed with 2no x 12m long pipe sections (the max length).

However, where the site restricts the headroom immediately above a pile position that same 24m long pile will now require more sections. If the sections were, say, 3m long, then it would take 8no sections to install that same 24m long pile.

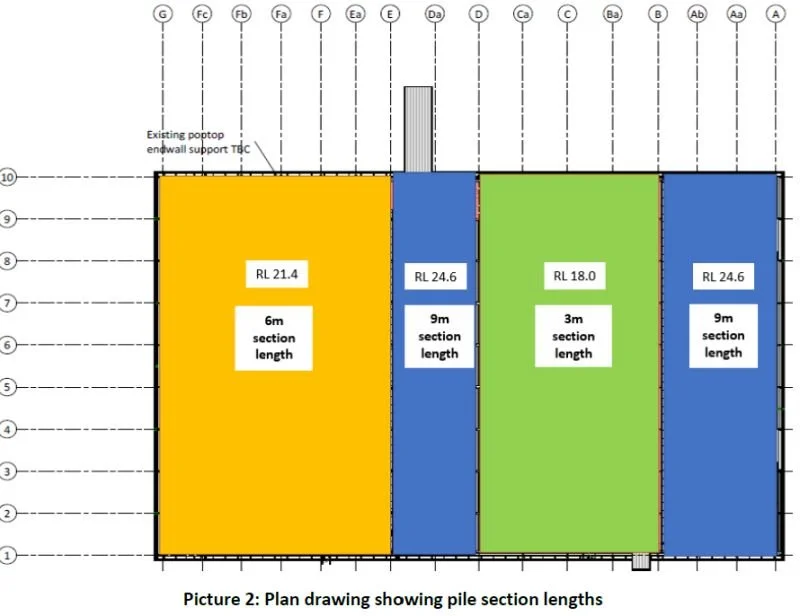

**See plan drawing showing an example site where Revex defined the section lengths within each gridline.**

SO WHY ARE "SECTIONS" IMPORTANT?

The screw pile materials below the ground required to deliver a job are fixed and don’t vary (whether low headroom or greenfields). However, the duration of plant and labour onsite is defined by productivity relative to the number of sections.

Screw Piling Productivity = sections/day.

(Note: bored piles typically measure in piles-per-day).

With respect to productivity – while every site is different – we tend to find that the time taken to track to the next individual pile location, pick a pile/pipe up, slew it over the top of the pile position, start installing (by screwing), disconnect and move towards the next pile is what takes the longest time. Relatively and generally speaking – the time screwing downwards is fast, and it is similar for a section that is 3m long as it is a 6m long section, 9m long or 12m long section.

So as screw piling installation is generally quick, we therefore define productivity as “sections per day”.

- When we are cramped in and can’t move much, or when ground conditions are tough, we might only get 10 sections/day.

- When less cramped, and ground conditions are move favourable, we might get as many as 20 sections/day….

- On open sites with good Geotech we can sometimes install north of 50 sections/day.

END RESULT

As an example this project had 121 piles going to 26.5m depths – but with the various head height restrictions – had a whopping 545 sections.

Our site team achieved the average target of 14 sections/day = 41 days. However, imagine the difference 3 sections per day would have, both faster and slower:

- 545 sections @ 17 sections/day = 32 days (9 days faster)

- 545 sections @ 11 sections/day = 50 days (9 days slower)

An example site where Revex defined the section lengths within each gridline.